Description

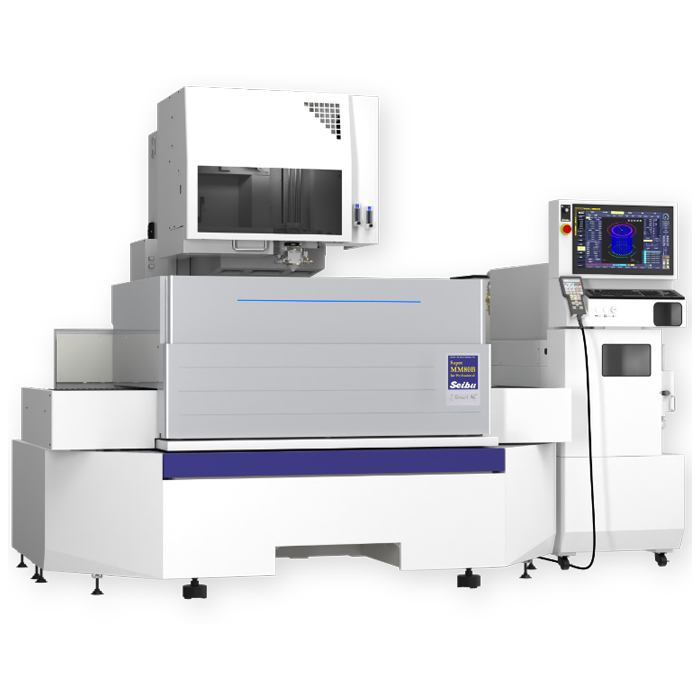

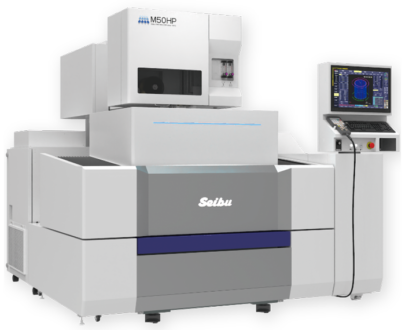

The SMM80B Ultra-Precision Wire EDM Machine sets a new standard in high-accuracy machining, achieving an exceptional ±1µm pitch accuracy with the largest cutting area in the series (800×600mm). Designed for precision metal cutting and die manufacturing, it supports large workpieces up to 1,000×800×150mm and includes an Automatic Wire Feeding (AWF-4) system for enhanced efficiency. The Smart NC control system features a 21.5-inch multi-touch TFT display, MDI, Ethernet, and USB input, and simultaneous 4-axis control, making it ideal for complex industrial applications.

Key Features:

✅ Ultra-precision ±1µm pitch accuracy

✅ Largest cutting area in the series (800×600mm)

✅ 5-axis control (simultaneous 4-axis operation)

✅ Automatic Wire Feeding (AWF-4) for continuous operation

✅ Smart NC control with a 21.5-inch TFT touch screen

✅ Advanced filtration & deionizer system for optimal performance

✅ Power-efficient operation with 11 kVA input

Ultra-precision machine

| Standard Specifications | SMM80B |

|---|---|

| Max. workpiece dimensions W×D×H |

1,000×800×150mm |

| Max. workpiece weight | 600kg |

| Axis travel range X×Y×Z |

800×600×230mm |

| Automatic wire feeging device | AWF-4 equipped as standard |

| U-V axis travel U×V |

±60× ±60mm |

| Max. taper angle | ±10°/work thickness 150mm (±45°/40mm: Option) |

| Dimensions W×D×H |

2,380×2,400×2,155mm |

| Weight | 6,300kg |

| Control device | Smart NC |

|---|---|

| Input system | MDI, Ethernet, USB |

| Display | 21.5 inch TFT multi-touch screen |

| Axis controlled | 5 axis (simultaneously 4 axis) |

| Least input increment | 0.01µm |

| Least command increment | 0.01µm |

| Program memory capacity | 1GB |

| Power Supply | MPSC-20 |

|---|---|

| Input power source | 3-phase 200V/220V±10% 11 kVA, 50/60Hz |

| Weight | 160kg |

| Filtration device | MF1100BD |

|---|---|

| Tank capacity | 1,100L |

| Filter element | 4 paper filters Φ340 ×300mm |

| Deionizer | Ion exchange resign 20L |

| Weight | 350kg |

Wire diameter : Φ0.10mm to Φ0.30mm

(Φ0.2mm is standard.)

Reviews

There are no reviews yet.